We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

close

Press esc to close

close

Press esc to close

close

Fill out your contact details below and our training experts will be in touch.

Back to Course Information

Module 1: Introduction to Lean 6 Sigma

Module 2: Reviewing Process and Qualities

Module 3: Yellow Belt Tools and Techniques

Module 4: Improvement Methodologies

Module 5: SPC Basics

Module 6: Lean Management and Cell Theory

Module 7: Risk Management

Module 8: DMAIC for Green Belts

Module 9: SPC Tools and Techniques

Module 10: Analyse Phase

Module 11: Improve Phase

Module 12: Control Phase

Module 13: Role of the Black Belt

Module 14: Black Belt DMAIC

Module 15: Enterprise Risk Management

Module 16: Physical Cell Design and Optimising Flow

Module 17: Black Belt as a Trainer

Module 18: Statistics Basics

Module 19: Process Capability

Module 20: Hypotheses Tests

Module 21: Exercise Using Minitab’s – 2 Proportion Test

Module 22: Exercise Using Minitab’s - Chi-Square Test

Module 23: ANOVA

Module 24: Data Collection Planning for Hypotheses Tests

Module 25: Design of Experiments (DOE)

Module 26: Probability Distributions

Module 27: Advanced Control Charts

Module 28: Measurement System Analysis (MSA)

Module 29: Lessons from Queue Theory

Module 30: Lean Metrics

The Lean Six Sigma Black Belt Training Course is for everyone who is interested in Business Performance Improvement. This course will be more beneficial for the following professionals:

There are no prerequisites for the Lean Six Sigma Black Belt Course. However, you will need to make the below-mentioned minimal arrangements before the commencement of the course:

This Lean Six Sigma Black Belt training course is the third Lean Six Sigma certification in our range.

This Black Belt training course is divided into two modules. The first module will teach Lean Six Sigma Yellow Belt, which outlines the main components of Lean Six Sigma. The first module will also cover the Lean Six Sigma Green Belt, which builds upon knowledge acquired at the Yellow Belt level and introduces the Define, Measure, Analyze, Improve and Control (DMAIC) model. The second module will focus on the Black Belt itself.

The Black Belt provides delegates with everything they need to establish themselves as Lean Six Sigma experts. Delegates will be introduced to a variety of tools they can use to analyse and identify where business developments should occur.

The Black Belt produces efficient managers who possess extensive analytical skills, which allow them to determine appropriate resolutions to business problems. By the end of the course, Black Belts will be able to implement DMAIC methodology effectively and be capable of delivering and managing Lean Six Sigma projects successfully.

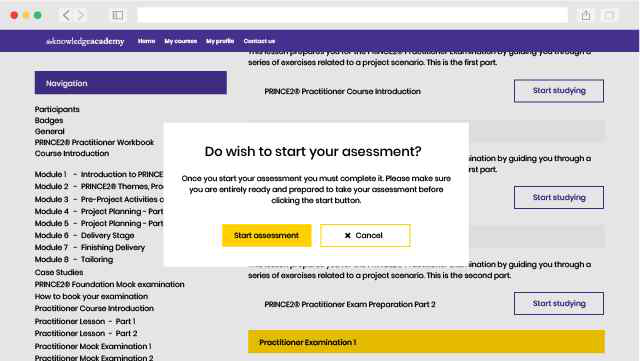

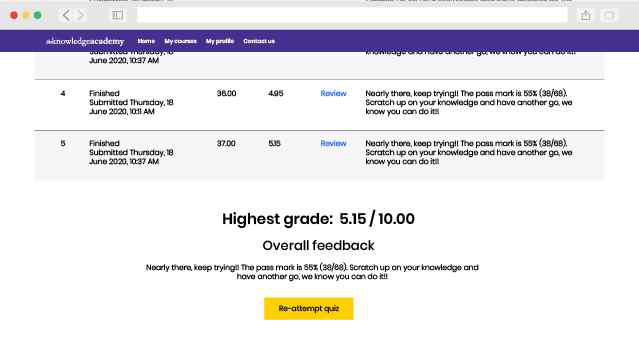

The Knowledge Academy's Lean Six Sigma Black Belt training course is divided into two modules. The first module will teach the Lean Six Sigma Yellow Belt, which outlines the main components of Lean Six Sigma. The first module will also cover the Lean Six Sigma Green Belt, which builds upon knowledge acquired at the Yellow Belt level and introduces the Define, Measure, Analyze, Improve and Control (DMAIC) model. The second module will focus on the Black Belt itself. Delegates are required to take and pass the Lean Six Sigma Yellow, Green and Black Belt Examinations to be Awarded with the Lean Six Sigma Black Belt Qualification.

To achieve the Lean Six Sigma Yellow Belt, candidates will need to sit for an examination. The exam format is as follows:

Delegates are required to attend the Lean Six Sigma Yellow Training Course before sitting this exam.

To achieve the Lean Six Sigma Green Belt, candidates will need to sit for an examination. The exam format is as follows:

To achieve the Lean Six Sigma Black Belt, candidates will need to sit for an examination. The exam format is as follows:

Why choose us

Our easy to use Virtual platform allows you to sit the course from home with a live instructor. You will follow the same schedule as the classroom course, and will be able to interact with the trainer and other delegates.

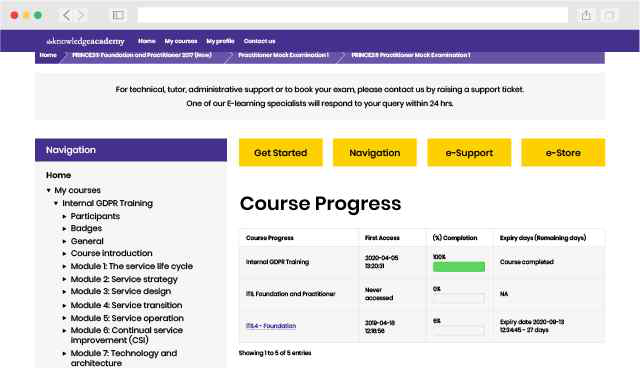

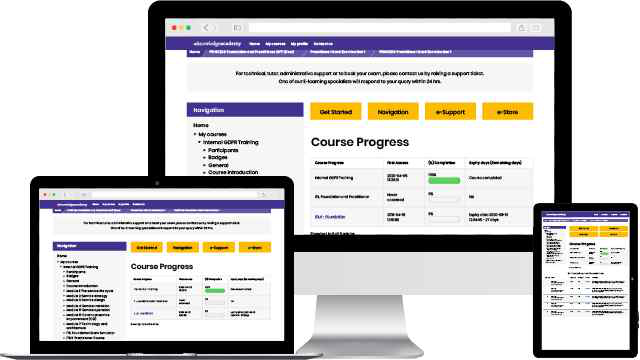

Our fully interactive online training platform is compatible across all devices and can be accessed from anywhere, at any time. All our online courses come with a standard 90 days access that can be extended upon request. Our expert trainers are constantly on hand to help you with any questions which may arise.

This is our most popular style of learning. We run courses in 1200 locations, across 200 countries in one of our hand-picked training venues, providing the all important ‘human touch’ which may be missed in other learning styles.

All our trainers are highly qualified, have 10+ years of real-world experience and will provide you with an engaging learning experience.

We only use the highest standard of learning facilities to make sure your experience is as comfortable and distraction-free as possible

We limit our class sizes to promote better discussion and ensuring everyone has a personalized experience

Get more bang for your buck! If you find your chosen course cheaper elsewhere, we’ll match it!

This is the same great training as our classroom learning but carried out at your own business premises. This is the perfect option for larger scale training requirements and means less time away from the office.

Our courses can be adapted to meet your individual project or business requirements regardless of scope.

Cut unnecessary costs and focus your entire budget on what really matters, the training.

This gives your team a great opportunity to come together, bond, and discuss, which you may not get in a standard classroom setting.

Keep track of your employees’ progression and performance in your own workspace.

Aubrey was fantastic - a true expert in his field who delivered many complex subjects in a way which was engaging and easy to understand.

Aubs was excellent, very engaging.

Aubrey Alexander was professional and great humored. His is a great trainer and takes his time to ensure everyone in the training understand and carries everyone along. I will be happy to further my training with Aubrey Alexander.

You won't find better value in the marketplace. If you do find a lower price, we will beat it.

Flexible delivery methods are available depending on your learning style.

Resources are included for a comprehensive learning experience.

"Really good course and well organised. Trainer was great with a sense of humour - his experience allowed a free flowing course, structured to help you gain as much information & relevant experience whilst helping prepare you for the exam"

Joshua Davies, Thames Water

History of Lean Six Sigma

History of Lean Six Sigma What are the benefits of Lean Six Sigma?

What are the benefits of Lean Six Sigma? Lean Six Sigma Examinations

Lean Six Sigma Examinations What organisations use Lean Six Sigma?

What organisations use Lean Six Sigma? Lean Six Sigma Methodologies

Lean Six Sigma Methodologies Lean Six Sigma Courses

Lean Six Sigma Courses Which sectors use Lean Six Sigma?

Which sectors use Lean Six Sigma? How do I book a Lean Six Sigma training course?

How do I book a Lean Six Sigma training course? How to add Lean Six Sigma to your CV

How to add Lean Six Sigma to your CV What if I fail my Lean Six Sigma training course?

What if I fail my Lean Six Sigma training course? How to add a Lean Six Sigma Certification to your LinkedIn profile

How to add a Lean Six Sigma Certification to your LinkedIn profile Lean Six Sigma Job Roles

Lean Six Sigma Job Roles Lean Six Sigma Case Studies

Lean Six Sigma Case Studies Who is Lean Six Sigma intended for?

Who is Lean Six Sigma intended for?

Back to course information

Back to course information

We may not have any package deals available including this course. If you enquire or give us a call on 01344203999 and speak to our training experts, we should be able to help you with your requirements.

If you miss out, enquire to get yourself on the waiting list for the next day!

If you miss out, enquire to get yourself on the waiting list for the next day!